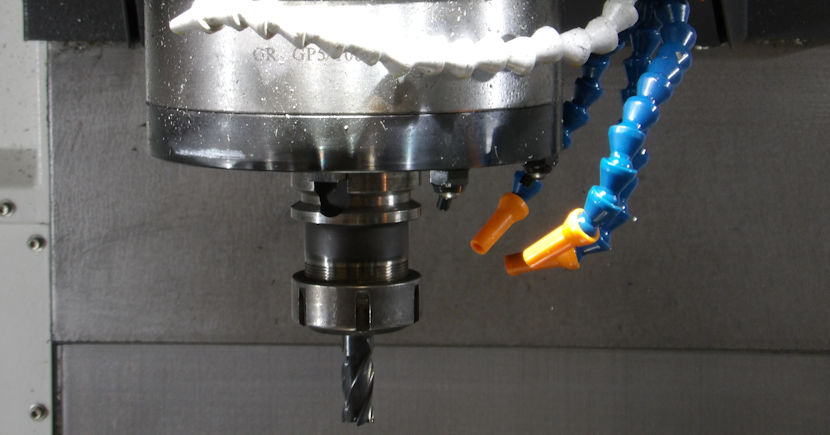

CNC Machining

Our CNC Machine Centres and CNC Lathes complement our other facilities where we can offer the complete package from conception, through design to full manufacturing of samples and then full production.

Our Victor CNC Lathes also have bar feeds which are capable of machining up to 60mm Dia bar and our larger CNC lathes are capable of machining up to 400mm Dia x 1200mm long

Our CNC Machining Centres can accommodate jobs up to a metre long and over 500mm wide which along with our manual machine shop and toolroom can offer small batch work and larger production numbers.

We can also offer Wire eroding upto 600 x 400mm with a maximum cutting thickness of 300mm.

Inhouse Toolroom

Our in-house toolroom also allows us to offer more conventional services:

- Turning

- Milling

- Grinding

- Wire Eroding

Configuration and Customisation

Quality Control System

Accurate Testing Processes

Professional, Quick & Competitive Service

Metool purchased it’s first CNC lathe from Ajax Victor in 1988 and has since developed a wide ranging machining facility of lathes and machining centres.

Allied with our other internal manufacturing we are able to offer customers not just machined parts but where applicable a full fabricated assembly provided by one source which helps us to provide a quick and competitive service.

Why Us?

Here at Metool we strive for quality and this has been a driving factor behind the strong reputation we've built.

We are approved to ISO 9001:2015 and recognised within our customer range as a company which maintains excellent standards of quality.

Even with our years of experience we still constantly strive to improve through employee development, training and more.

Our ability to produce our own tooling for our wide ranging capacity has allowed us to develop into a company with a flair for taking on the difficult types of components. This has enhanced our reputation with a number of blue chip companies and other smaller organisations.

Our company philosophy is at the heart of everything we do. We are committed to quality in both our products and services.

Our aim is to be known as a ‘Service Provider’ with a concept of building long term relationships with our customers. To achieve this we place great emphasis on our reputation for delivering on time and our ability to cope with minimal lead times.

Due to continued heavy investment we are equipped with the very latest in engineering technology, giving us the ability to provide a one stop shop solution for customers in various industries.